[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

وظيفة النظام | ز كود | ||||||||

عدد محور التحكم | 3-5 محور | تحديد المواقع | G00 | مثقاب نقر عالي السرعة | G73 | ||||

أصغر برمجة: | 0.0001 مللي متر | الاستيفاء الخطي | G01 | دورة مكافحة التنصت | G74 | ||||

الأكثر برمجة: | ± من من | استيفاء القوس | G02/G03 | الانتهاء من دورة مملة | G76 | ||||

أعلى سرعة: | 60 م/دقيقة | ترهل ، شرط وقفة | G04 | إلغاء دورة ثابتة | G80 | ||||

سرعة التغذية: | أو ~ 15 م/دقيقة | كشف السفر الذاكرة | G12/G13 | دورة الحفر (دورة الحفر الموضعي) | G81 | ||||

دليل مستمر: | محور واحد أو محور متعدد في نفس الوقت | قيادة النظام القطبي | G15/G16 | دورة الحفر (دورة حفر حفرة متدرجة) | G82 | ||||

استيفاء الخط: | خط مستقيم ، قوس ، استيفاء الخيط اللولبي | اختيار الطائرة | G17/G18/G19 | دورة الحفر بيك | G83 | ||||

تعويض الأداة: | تعويض الطول 、 نصف قطر الأنف من أداة التعويض ، أداة تعويض التآكل | بوصة/نظام متري | G20/G21 | CW دورة التنصت | G84 | ||||

إعداد الأداة | إعداد أداة تحديد المواقع ، إعداد أداة قطع تجريبية ، إعداد أداة النقطة المرجعية | تخشين الدائرة الداخلية للأخدود (CCW)/(CW) | G22/G23 | دورة مملة | G85 | ||||

إدارة الأدوات | أداة إدارة الحياة | تشطيب الدورة الداخلية (CCW)/ (ث ث) | G24/G25 | Boring cycle | G86 | ||||

وظيفة آخر أداة | وظيفة أداة الصف ، وظيفة أداة كهربائية ، منشور (اختياري) ، وظيفة أداة مؤازرة (اختياري) | تشطيب الدائرة الخارجية (CCW) | G26 | دورة مملة الظهر | G87 | ||||

وظيفة المغزل: | التحكم التناظري ، التنصت الناعم | كشف عودة الموقف المرجعي | G27 | Boring cycle | G88 | ||||

وظيفة عقارب: | لوحة 、 محمول باليد | عودة الموقف المرجعي | G28 | برمجة مطلقة | G90 | ||||

معالجة عجلة يدوية: | وظيفة معالجة عجلة اليد | العودة من الموضع المرجعي | G29 | برمجة تدريجية | G91 | ||||

التسارع والتباطؤ | خطي ، نوع S ، أسّي | عودة المركز المرجعي الثاني والثالث والرابع | G30 | إعداد نظام تنسيق عائم | G92 | ||||

وظيفة الاتصالات: | واجهة USB | وظيفة تخطي | G31 | تغذية في الدقيقة | G94 | ||||

وظيفة التعويض: | أداة تجميع 、 تعويض نصف القطر | تشطيب الدائرة الخارجية (CW) | G32 | تغذية لكل roatation | G95 | ||||

برنامج التحرير: | متري/بوصة | تخشين الأخدود مستطيل (CCW)/(CW) | G33/G34 | سرعة دورة ثابتة (سرعة القطع) | G96/G97 | ||||

وظيفة الطباعة: | Preread ، خطوط مستقيمة قصيرة | تشطيب داخلي مستطيل الشكل (CCW)/(CW) | G35/G36 | عاد إلى الطائرة الأولى في دورة ثابتة | G98 | ||||

حماية كلمة المرور: | حماية بكلمة مرور متعددة المستويات | تشطيب خارجي مستطيل (CCW)/(CW) | G37/G38 | العودة إلى نقطة R في دورة ثابتة | G99 | ||||

الإدخال/الإخراج: | I/O 24*24 | زاوية تعويض قوس الاستيفاء | G39 | ||||||

PLC: | التصميم الداخلي ، دعم التحرير عبر الإنترنت ، دعم برنامج muti PLC | إلغاء التعويض القاطع | G40 | ||||||

عدد التشفير: | 1 | تعويض القاطع يسار/يمين | G41/G42 | ||||||

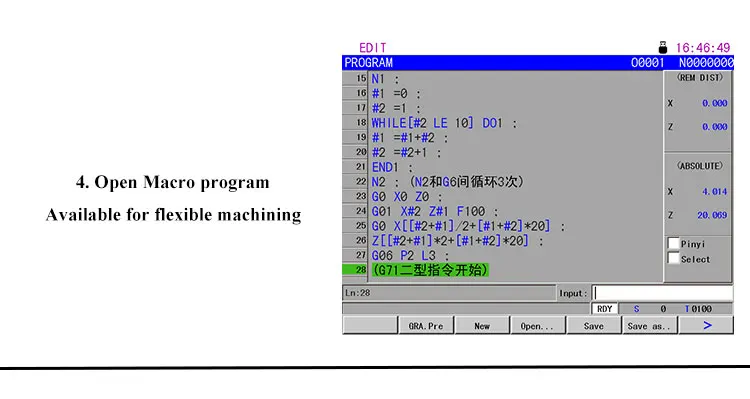

برنامج ماكرو المستخدم: | نوع أ/ب | طول الأداة اتجاه التعويض إيجابي/سلبي | G43/G44 | ||||||

وظيفة العتاد الكهربائي: | دعامة | إلغاء تعويض طول الأداة | G49 | ||||||

الحد | الحد الصلب ، الحد لينة | إلغاء التحجيم | G50 | ||||||

تشخيص | تشخيص IO ، تشخيص PLC | التحجيم على | G51 | ||||||

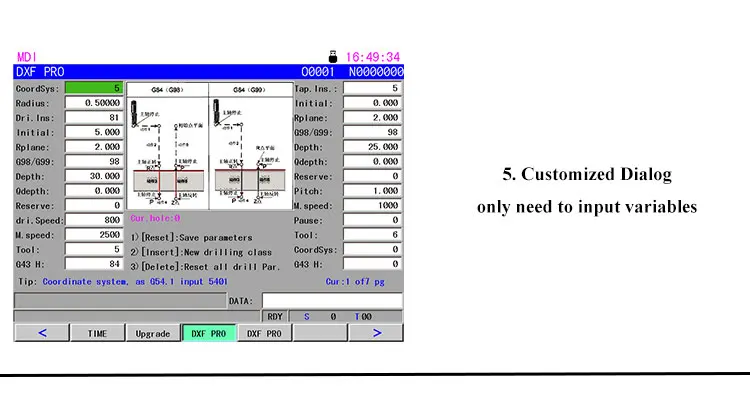

حوار المستخدم المخصص | Support | نظام تنسيق الماكينة | G53 | ||||||

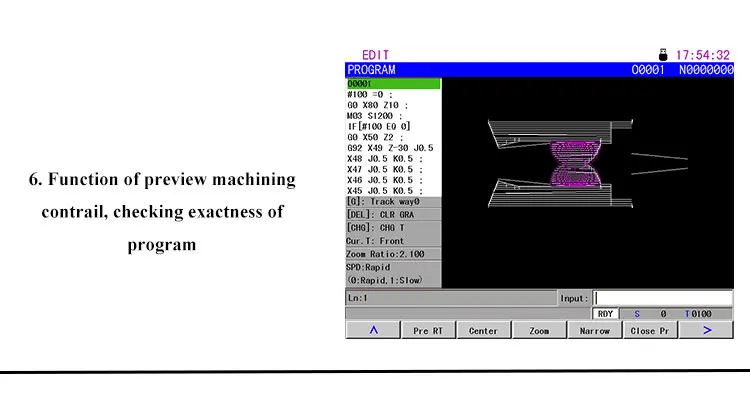

معاينة البرنامج | Support | تنسيق الشغل | G54 ~ G59 ، G54.1 ~ G54.50 | ||||||

كود CAD to G | دعم (وظيفة اختيارية) | تحديد اتجاه واحد | G60 | ||||||

متعدد المحاور صفر العودة | Support | اختيار وضع الموقف | G61 | ||||||

Compesnation رد فعل عنيف | Support | نسبة زاوية تلقائية | G62 | ||||||

لوحة فرعية | عجلة يدوية ، مفتاح (اختياري) | وضع التنصت | G63 | ||||||

التطبيق: | آلة طحن ، مركز الطحن | وضع القطع | G64 | ||||||

وظيفة ATC | نوع خطي ، نوع مظلة ، اليد الميكانيكية | برنامج ماكرو | G65 | ||||||

اللغة | الإنجليزية والروسية (اختياري) | إحداثيات دوارة | G68/G69 | ||||||

توقَّع توصيل طلبك إليك قبل التواريخ المحددة أو احصل على تعويض بنسبة 10% عن التأخير

يتم تأمين كل دفعة تقدمها على Cooig.com باستخدام تشفير SSL صارم وبروتوكولات حماية بيانات PCI DSS

طالِب باسترداد الثمن إذا لم يُشحن طلبك، أو فُقد، أو وصل مع وجود مشكلات في المنتج

تمتع بوصول إلى قطع غيار وتغطية إصلاح مجانية